Functional principle

iiMES molecules are attracted and stick to surfaces by surface tension. They penetrate the metal surfaces changing their properties and allowing horizontal forces to flaten their surface structure in motion.

Our formulated Concentrates are hydro-carbon based and react with hot surfaces. Due to the crystal lattice structure of metals their electrons are very reactive. Hot metal surfaces increase this effect and a transformation takes places almost isochronally.

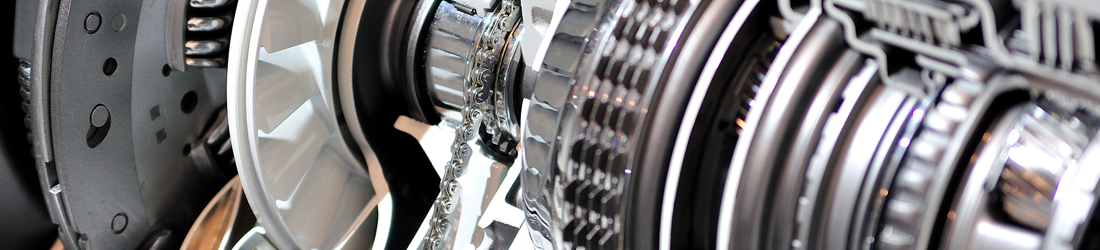

Heat sources within machines are mainly the friction surfaces where the major wear occurs. When iiMES concentrates are used under heat and pressure, our especially developed molecules diffuse into the metal surfaces (crystalline structure). The subsequent chemical-metallurgic process changes a 4-7 µm thin layer of the original metal into a new metal type which is way harder and significantly more wear-resistant (alloy). During the conversion process, all impurities like moisture, rust, deposits as well as residues are displaced and given to the carrier liquid. Hereinafter, all treated metals are dirt-, dust- and water-repellent.

The new metal surface changed by iiMES products is very thin and elastic. It serves as protective layer and prevents a breaking off of metal parts in the event of collision but allows the underlying original metal to move horizontally with the horizontal force resulting from the collision. Thus, the metal, the “hill”, is moved into the “valleys” and enables an active grading of the friction surfaces (also see Documentation and Video).

This way, friction is reduced and efficiency as well as service life are substantially increased. The technology of liquid hardening prevents material failure. Metal surfaces are refined and sealed. Joints and gaskets are cleaned and lubricated and thus also have a higher lifespan.

With the use of iiMES lubricant and preservative, your machines and devices experience a renewal from within.

In summary, the following advantages arise

iiMES molecules..

- ..are applicable on all metal surfaces

- ..clean the surfaces and displace deposits

- ..make the surfaces dust and water repellent

- ..reduce friction by active transformation of the surface structure

- ..reduce the wear of treated surfaces also in case of dust and dirt contamination

- ..protect against corrosion and electrical oxidation

- ..enable cold starting at up to -40°C

- ..are hydro-carbon based and free of solids

- ..build a resistant and flexible micro metal coating from the original metal